A Portadown embroidery firm has opened new premises and increased its production by almost 70 per cent following a six-figure investment supported by Ulster Bank.

As part of its expansion plans, C&G Embroidery has invested in the development of new, purpose-built premises that will enable the business to increase its product range and significantly boost output.

The new premises include a larger factory floor with capacity to introduce additional machines to facilitate future growth and demand and new showroom will enable the business to grow its product range which includes a large catalogue of work wear lines.

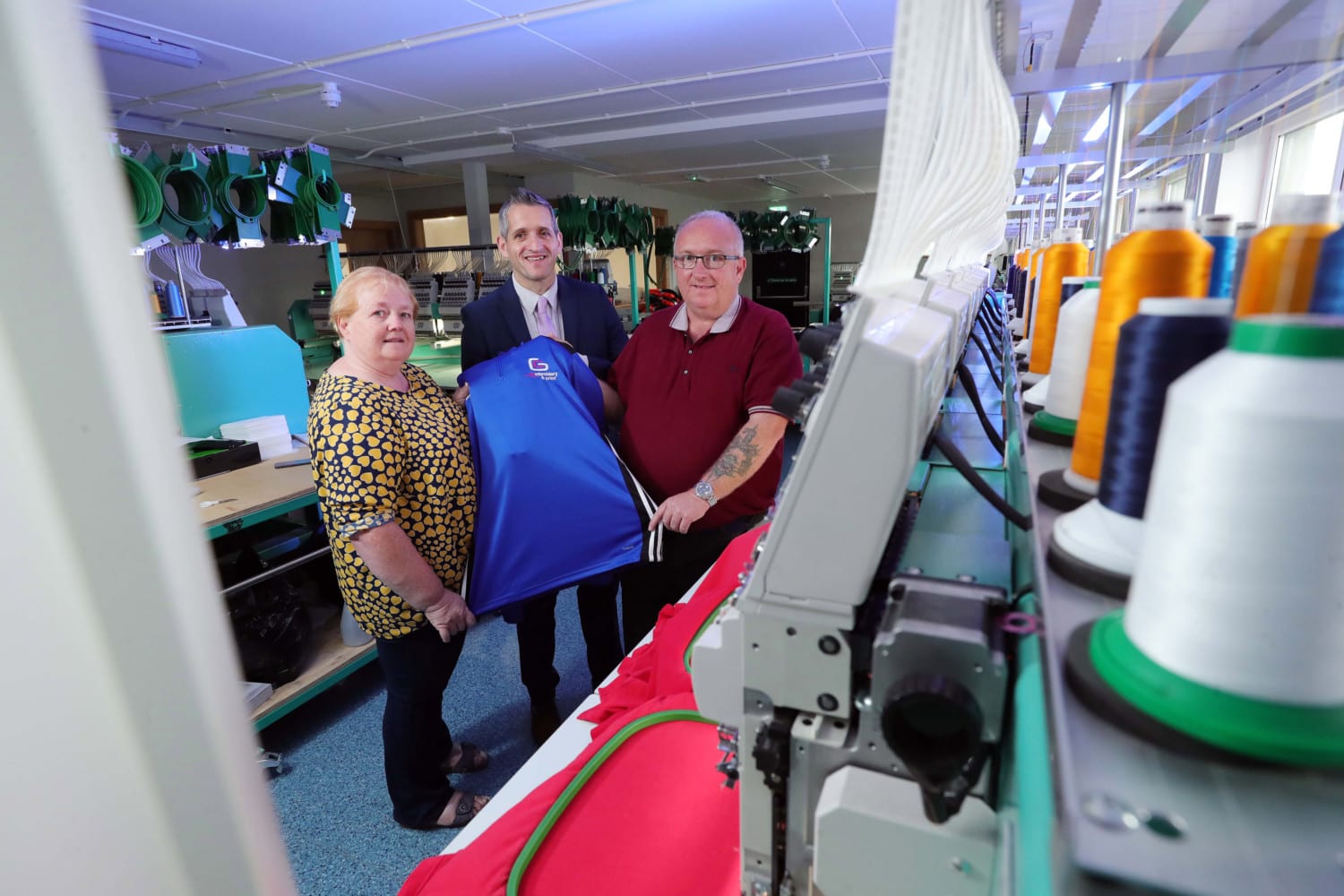

C&G Embroidery was established in 2007 by local businessman Gary Winter, whose family, including his wife, Carol, mother and father, have a long history of working the textiles industry.

The business provides embroidery and printing services to the hospitality and tourism industries, schools, sports clubs and other businesses across the UK and Ireland.

It began as a small start-up venture with one machine which was financed by Gary’s mother, a seamstress and dressmaker.

Now, C&G Embroidery employs eight operators with as many machines running at full capacity and producing up to 600 garments per day.

As part of the investment the business has purchased an additional “multi-head” embroidery machine that will support an almost 70 per cent boost in production to 1000 garments per day.

Paul Reid, business development manager at Ulster Bank, said: “Ulster Bank is very pleased to support Gary to invest in C&G Embroidery and put in place a foundation that will enable the business to continue to grow.

“Its new premises will help position the company as one of the premier embroidery and print specialists in Northern Ireland.

“The new facilities are designed with efficiency in mind. A streamlined factory setting will enable the company to sustain its current high output with the infrastructure and equipment to accommodate future growth.”

Gary said the expansion will help the business to attract more high-value contracts.

“Our customer base is continuing to grow and so too is the value of the work we are doing,

“We’re experiencing huge demand for our services and were operating at full capacity in our old factory.

“We were limited by space which was significantly impacting on hourly and daily production output as valuable time was lost as a result of the costly process of double handling materials.

“With the support of Ulster Bank, the investment in larger premises has enabled us to streamline our processes and generate an additional two hours per day of production time. It has also provided us with the infrastructure to accommodate future growth and compete for larger contracts.”